lee brinell hardness tester|brinell hardness tester instructions : suppliers Pure lead is beyond the range of our hardness tester. Pure lead has a hardness of 5 on the Brinnell scale, which would approximately be a .094 diameter indentation. . — Lee Shooter Program 3 — Reloading Stand & Bench Plate 75 — Powder Handling 31 —— Disk Powder Measures 3 —— Classic Powder Measure 5 —— Perfect Powder Measure . In autoclaves, the Geobacillus stearothermophilus spore is used. Unlike mechanical or chemical indicators, spore testing determines that spores – the most resistant microorganisms – have been killed during sterilization.

{plog:ftitle_list}

In this section the preparation and assembly of low, medium and high pressure connections is explained. Also covered is the assembly procedure for medium and high pressure Cone & .The Large autoclave comes in different volumes, the structure is made of high quality stainless steel, the side panels open and allow easy access to the steam systems, vacuum, faucets, piping, control systems, electricity and protection.

Lee Lead Hardness Test Kit will determine the exact Brinnell Number of an alloy .The Lee Lead Hardness Testing Kit will determine the exact Brinnell Hardness Number of an .

A key component of Brinell hardness testers, these ball indenters are hard enough to make impressions on most metal. Made of carbide, they won’t deform as they press into hard material. Shallow indentations mean a material is hard and deep indentations show that it is soft. Use the diameter of the indentations created by these balls as part of the calculation to find your .

The WIKI for the Brinell hardness testing, the real subject of this article is here: . They include the Saeco Tester, the Lee Hardness Tester, and the Cabine Tree Tester. Saeco Tester. The Saeco Tester has a limitation in that you can only check small samples, typically an actual cast lead bullet. And, the use of that tester requires visually . Pure lead is beyond the range of our hardness tester. Pure lead has a hardness of 5 on the Brinnell scale, which would approximately be a .094 diameter indentation. . — Lee Shooter Program 3 — Reloading Stand & Bench Plate 75 — Powder Handling 31 —— Disk Powder Measures 3 —— Classic Powder Measure 5 —— Perfect Powder Measure . A 5-minute video covering the basics of cast bullet hardness and demonstrating Lee Precision's Lead Hardness Tester.Los Angeles Silhouette Club's Cast Bullet.

In this PounderLabs video we discuss Brinell hardness testing for metallic lead and its alloys, give some important history about Brinell and Meyer and how t.

The Lead Hardness Tester Standard Model is one of the easiest to use lead testers on the market. Use for testing cast bullets and ingots. Features a large and easy to read dial indicator. A conversion chart for SAECO and Brinnell is included. Unit is all steel, weighs approximately 5 lbs, with a black oxide finish. Testing an ingot. Install the dial indicator on the holding rod and .

The Lee Lead Hardness Test Kit is a component for your reloading equipment. It offers a quick and easy way to determine the exact Brinnell Hardness Number of an alloy. It will save you time and components by ensuring you dont work with the wrong alloy. FEATURES.The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.

This is the start of a series of videos regarding alloy hardness. I'd like to share my technique with you regarding how I use the Lee Hardness Tester. If you. One of those articles is a comparative test of most of the common lead hardness testers. Participants did blind tests of sample bullets all cast in the same lot. I was one of the LBT testers using a 30 year old tool that agreed well with the standard results. The standard result was from a calibrated commercial brinell test machine in a metals lab.The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.Find many great new & used options and get the best deals for LEE PRECISION Lead Hardness Test Kit - 90924 at the best online prices at eBay! Free shipping for many products!

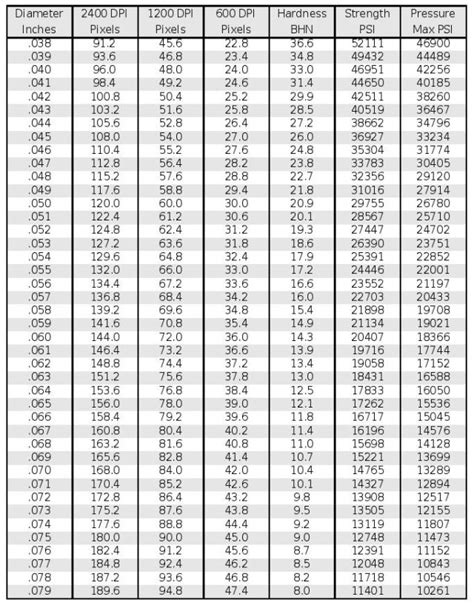

lee brinell hardness tester chart

3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

brinell hardness testing machine diagram

Lee Precision’s Lead Hardness Test Kit In this article we’ll be taking a look at Lee Precision’s Lead Hardness Test Kit. The first thing people usually ask about these is why you’d ever want to test the hardness of cast bullets to begin with. . This yields a bullet of roughly 18 on the Brinell hardness scale and that’s I’ll be .Microscope stand for use with the Lee Lead Hardness Test Kit, product 90924 • Enables hands-free operation of the Lee Pocket Microscope from the Lee Lead Hardness Test Kit • Adjustment knobs allow for 1/2" of vertical travel • .Another criticism of the Lee unit is it does not measure below 8 on the Brinell scale. The issue here is that ‘pure’ lead is quoted at 5 Brinell so a hardness tester should measure to this level. Lee belief that softer than 8 is almost pure lead and as such .The Newage KB Series is a popular, manually-controlled Brinell hardness tester that meets ASTM E-110. This lightweight, portable tester is ideal for virtually any size or shape of metal specimen. Keep Reading. Pin Brinell Hardness Tester. The Pin Brinell is a cost effective instrument, which uses a calibrated shear pin to control the amount of .

The Lee Lead Hardness Test Kit by Lee Precision is useful to find the Brinell Number of an alloy in a 6 step process. Lee Pocket microscope is included. Free Shipping on Orders over 0 to most of Canada.

The Wilson BH3000 Brinell Hardness Tester stands as a robust Brinell hardness tester, boasting a wide range from 62.5 kgf to 3000 kgf. Crafted with rugged construction for resilience in challenging environments, this reliable hardness tester blends high rigidity and closed-loop load cell technology to ensure precise and secure load applications. Brinell Indentation Diagram. In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron.

Lee Mangham is the Technical Manager at the Element Sheffield laboratory, he is responsible for a wide variety of technical content and has over 30 years of experience in mechanical testing. . The Brinell hardness test (HBW) serves as a crucial scale for quantifying material hardness, defined in ASTM E10 and BS EN ISO 6506-1 standards. .

The Lee Lead Hardness Test Kit will determine the exact Brinnell Number of an alloy in a simple 6 step process. Included is the Lee Pocket Microscope. WARNING: Lead - Discharging firearms in poorly ventilated areas, cleaning firearms, or handling ammunition may result in exposure to lead and other substances known to cause birth defects .There are two types of Leeb hardness testers such as bench (stationary, classical) as well as portable (mobile, electronic). Bench hardness tester– This bench hardness tester is a traditional type used to determine the hardness of a sample employing the standard methods of Rockwell, Vickers, Brinell, or Shor.Hence, they can be called ‘bench Rockwell hardness tester’ or ‘bench .speed and reduced operator nfluence on the test results. S nce no opt cal measurements are made, d fferent operators w ll cons stently prov de except onally repeatable test results. L ke the Rockwell hardness test method, th s depth measurement s calculated based on the d fference n penetrat on depth between a preload and a major load pos t on.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion resistance).The Lee Lead Hardness Test Kit is a component for your reloading equipment. It offers a quick and easy way to determine the exact Brinnell Hardness Number of an alloy. It will save you time and components by ensuring you dont work with the wrong alloy. FEATURES To .

describe autoclaving process

In this Video I demonstrate the Lee Precision lead harndess testing kit for cast bullets. With this kit you can check the Brinnell hardness of your lead cast.

describe the use of an autoclave in microbiology laboratory

brinell hardness testing charts

Idromar International was founded in 1982, when water-makers for nautical use were practically unknown. His great love for the sea and boating, led Vittorio Battino to construct the first water .

lee brinell hardness tester|brinell hardness tester instructions